LED airport rotating beacon light,ICAO "Airport Service Manual" Part 9 "Airport Maintenance Practices" and FAA's AC150/5345-26 "Airport Visual Aiding Equipment Maintenance" is the highest standard for on-site installation and maintenance of lamps, this manual is in the process of preparation, a large number refer to these two standards.

Description:

ICAO "Airport Service Manual" Part 9 "Airport Maintenance Practices" and FAA's AC150/5345-26 "Airport Visual Aiding Equipment Maintenance" is the highest standard for on-site installation and maintenance of lamps, this manual is in the process of preparation, a large number refer to these two standards.

The contents described in this manual are extremely important, and the construction personnel must read it carefully before construction. After correctly understanding all the contents, strictly follow the method specified in the manual to ensure safe and correct installation of the product in place.

The daily maintenance personnel of the airport should do the routine maintenance work in strict accordance with the relevant regulations to ensure that the lamps are in the best working condition.

Relevant personnel must strictly abide by the safety guidelines. Non-specialized personnel are strictly prohibited from touching the lamps and equipment. In any case, live work should be avoided. Construction personnel or maintenance personnel should be aware of relevant first aid knowledge to prevent emergencies.

Safety Rules and Precautions:

lIt is strictly forbidden to use this luminaire outside the airport. Insufficient maintenance or irregular operation may cause lamp failure.

lThe weight of the rotating lamp is large. When transporting, the disc and the outer casing cannot be pulled directly. The force should be directly applied to the base.

lBe sure to be powered off before installing and maintaining the luminaire.

lNon-professional electricians are strictly prohibited to maintain electrical faults in the lamps.

lIt is strictly forbidden to maintain the lamps with electricity. It is forbidden to maintain the lamps during lightning storms. It may cause an electric shock.

lCare should be taken when handling the lamps.

lWhen the wire skin is damaged, replace the lead wire immediately. There may be accidents such as short circuit and electric shock.

lWhen cleaning the lamps, please bring clean gloves.

Lighting Application:

This manual describes the apron rotating beacons manufactured to FAA AC 150/5345-12 and ICAO Annex 14 and the Airport Design Handbook. Please use the lamp in strict accordance with the relevant regulations of FAA and ICAO.

Technical Characteristics:

lLight intensity, light color meets the requirements.

lPrecision optical control, high light utilization, high brightness and outstanding optical performance.

lThe overall appearance of the lamp is beautiful, the heat dissipation performance is good, and the design is reasonable.

lThe luminaire adopts a split structure to reduce impurities and moisture into the lamp, which improves the service life of the luminaire optics and reduces the number of maintenance operations.

lThe main body of the lamp is made of aluminum alloy, and the fasteners are made of stainless steel, which has good anti-corrosion performance.

lThe use of high-precision machine tools ensures the omnidirectional quality and precision of the luminaire.

Product's Specification:

| Item | Parameter |

|---|---|

| Item Name | Airport/Heliport LED Rotating Beacon Light |

| Model No. | CM-HT12-4-XZ |

| Operating Voltage | AC220-240V,AC90-110V (other voltage is available) 50-60Hz |

| Power Consumption | 300W for White,60W for Green |

| Flashing Frequency | 12 rpm, 24 flashes/minute |

| Light Intensity | 25000cd-50000cd |

| Light Source | LED |

| Life span for light Source | 100,000 hours |

| Emitting Color | White&Green |

| Ingress Protection | IP65 |

| Altitude | no more than 2500m |

| Operating Temperature | -40℃- +55℃ |

| Wind Load | 240km/h |

| Weight | 85kg |

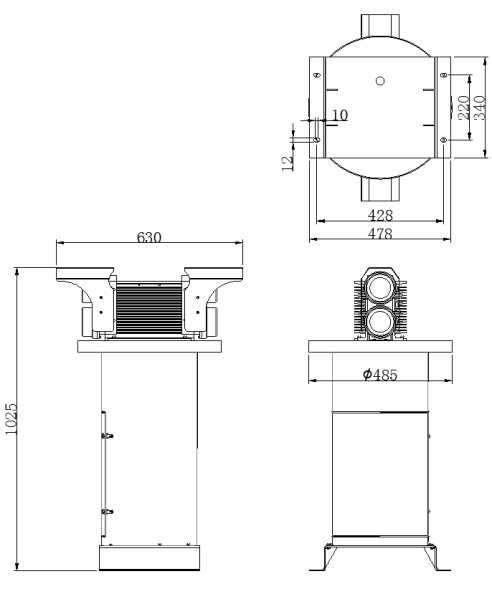

| Overall Dimension(mm) | 630*485*1030 |

| Installation Dimension(mm) | 428*220*M10 |

| Standard | FAA specification AC 150/5345-12 L801A |

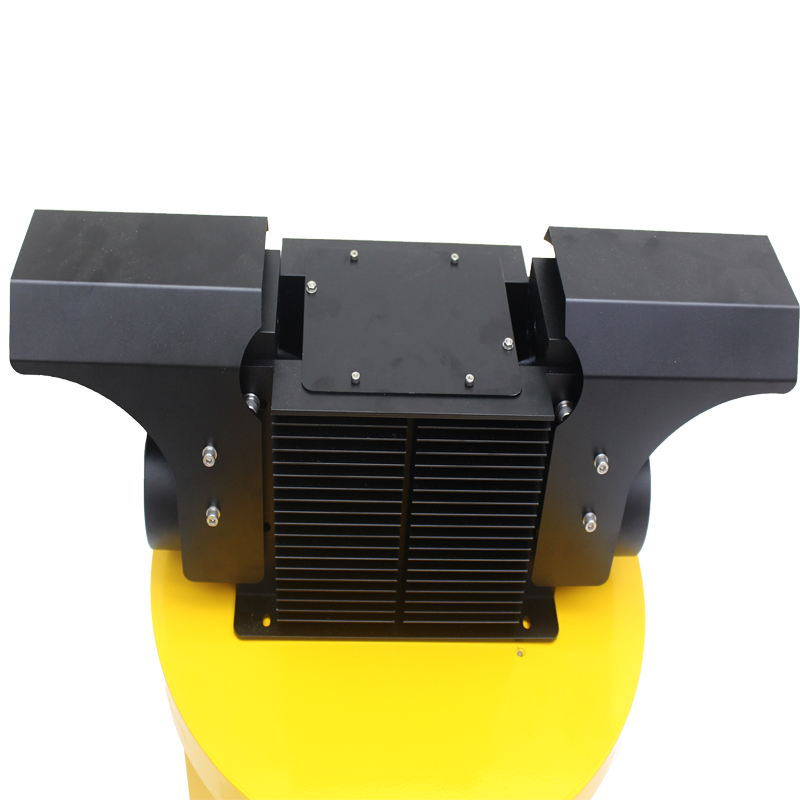

| Material | Housing in aluminum alloy,coated in yellow.Lamp heads are aluminum alloy |

| Feature | 4 lamps head,using high brightness CREE Leds |

Product's Structure and Dimmension:

Light Installation:

Before installing the luminaire, you should have an in-depth understanding of the installation requirements of the luminaire, including installation tools and site requirements. Avoid affecting the normal operation of the luminaire due to incorrect installation of the luminaire.

1. Installation Way:

lIf it is installed on a flat floor (such as concrete floor), fix the baffle to the concrete floor with expansion screws.

lIf it is installed on an uneven ground (such as land) in this case, it needs to be fixed on the concrete block.

2. Installation Step

lClean up the site and level the floor of the installation floor to ensure that the fixtures remain level after installation.

lWhen unpacking, check that the parts are complete. Handle the fixture carefully to avoid damage.

lFix the luminaire through the bottom plate screws and open the cover to connect the cable. L is connected to the Live Wire, N is connected to the Naught Wire, and the E is the Earth Wire (as shown in the figure).

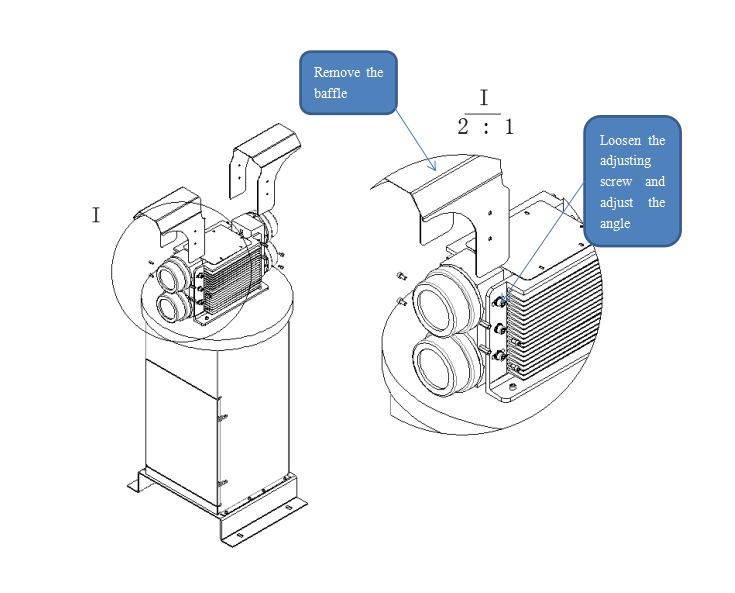

3. Adjust elevation angle of lamp

Remove the baffle, loosen the side screws, and adjust the elevation angle of the lamp through the front and rear angle adjustment screws until the predetermined angle value is adjusted to tighten the screw.

Maintainance:

Remove the baffle, loosen the side screws, and adjust the elevation angle of the lamp through the front and rear angle adjustment screws until the predetermined angle value is adjusted to tighten the screw.