Heliport rotating lights is adopted high brightness lamp source as white,yellow and green, whose weight is heavy, transport can not directly pull the disc and the outer shell, the force should be directly on the base.3-color heliport beacon light manufactured to FAA AC 150 / 5345-12 and ICAO Annex 14 and Airport Design Manual.

Description:

ICAO Airport Services Manual, Part 9, Airport Maintenance Practices, and FAA AC150 / 5345-26, "Visual Maintenance of Airport Visual Aids", are the highest standards for site installation and maintenance.

The manual is extremely important, construction workers must be read carefully before constructing. In the correct understanding of all the words, in strict accordance with the instructions provided by the method of construction, to ensure safe and correct product will be installed in place.

Airport daily maintenance works should be in strict accordance with the relevant provisions of the method of routine maintenance work to ensure that lamps are in the best working condition。

Relevant personnel must strictly comply with safety guidelines. Non-specially trained personnel should not touch lamps and equipment. In any case, Opening Electrical Power work should be avoided. Construction workers or maintenance person should be aware of the relevant emergency knowledge to prevent emergencies.

Safety codes and Precautions:

lIt is forbidden to use this lamp outside the airport. Inadequate maintenance or non-standard operation may cause lamp failure.

lRotating lights is heavy weight, transport can not directly pull the disc and the outer shell, the force should be directly on the base.

lBefore installation and maintenance of lamps should ensure that the power is off.

lNon-professional electrician is strictly forbidden to maintain the lamp electrical fault.

lIt is forbidden to maintain the lamps when power is open, and to prohibit the maintenance of the lamps when the thunder and lightning are rainy. It may cause electric shock accident.

lWhen transport,It should be carefully.

lWhen there is damage to the skin of the wire, replace the pin-out immediately. May cause short circuit, electric shock and other accidents.

When carrying out lamp maintenance, please wear dry gloves.

Using range of heliport beacon light:

This handbook describes apron rotation beacons manufactured to FAA AC 150 / 5345-12 and ICAO Annex 14 and Airport Design Manual. Please strictly follow the FAA and ICAO and other relevant provisions of the norms of the use of the lamp.

Products Features:

? Light intensity, light color meet the requirements.

? Sophisticated optical control, light utilization, high brightness, outstanding optical performance.

? Lamps shape is handsome, good thermal performance, well-designed.

? The lamp uses a split structure, reducing impurities and moisture into the lamp, improving the service life of lamp optics, reducing the number of maintenance operations.

? The main body of the lamp is made of aluminum alloy, the fastener is made of stainless steel, and the anti-corrosion performance is good.

? Adopts high-precision machine tool processing, ensuring a full range of lamps quality and accuracy.

Technical Specification:

? Halogen lamp:3*150W

? Lamp Using Life: ≥1000 hours

? White,Green,Yellow Color

? Lamp angle can be adjusted

? 12 rev / min, 36 times per minute flash

? 304 Steel cabinet with powder layer

? Voltage:AC220V

? Altitude below 2500 meters;

? Outdoor: -40 ℃ - +55 ℃;

? Relative humidity: 95%; (+ 24.5 ℃), the maximum humidity can be greater than 100%;

? Rain, snow, ice, water;

? Corrosive salt spray.

| Item Name | Heliport Rotating Beacon Light |

| Item No. | CM-HT12-3-XZ |

| Lamp type and color | Halogen lamp with 3 color for white,yellow and green |

| Voltage and frequency | AC110V,AC220-240V,50-60Hz |

| Flashing mode | 12rpm,36 times per minute flash |

| Function | Lamp can be adjusted |

| Material | 304 steel cabinet with powder layer |

| Altitude | Altitude below 2500 meters |

| Working environment | -40℃ - +55℃ |

| Protect Ingress | IP65 |

| Relative humidity | 95% (+24.5℃)the maximum humidity can be greater than 100%. Rain,snow,ice,water and corrosive salt spray |

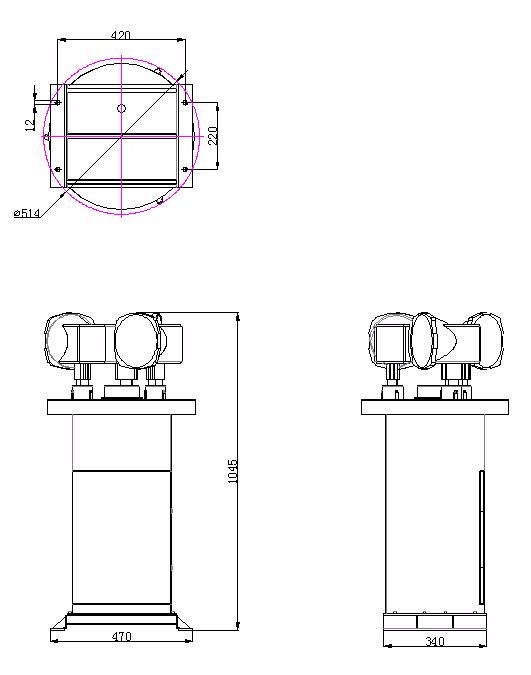

Light Structure:

Lamp Installation:

In the lighting installation, the installation of lamps should be in-depth understanding of the requirements, including installation tools, site requirements. Avoid the lamps and lanterns due to improper installation of the normal work.

1. Installation Way:

① If installed on a flat surface (such as concrete floor), the baffle with expansion screws on the concrete floor

② If installed in uneven ground (such as land) in this case, you need to be fixed in the concrete block.

2. Installation Steps:

① Clean the site, install the floor leveling, to ensure that the lamp is installed after the completion of the level.

② When open the package, check that the parts are complete and handle lamps carefully to avoid damage.

③ Fix the lamp through the bottom plate screw and open the cover to connect the cable.

Adjust the angle of lamp:

Check the lamp pointer engraved clearly visible, loosen the side of the set screw, adjust the lamp elevation angle through the front and rear angle adjustment screw until the pointer points to a predetermined angle value, locking the set screw.

Lamp's maintenance:

The routine maintenance recommendations provided in this section are for informational purposes only. The airport may establish its own routine maintenance guidelines based on other regulations or the maintenance experience of the airport staff themselves.

Airport lighting maintenance, please refer to "1.0 Foreword" described, by professionals.

Interval | Reference | Action |

Every day | Lamp failure | Change Lamp |

Light output is low | 1. If the glass surface is dirty, wipe it clean 2. Check lamp deviation or moisture 3. Check lamp aging or shifting | |

Every Week | Light output channel obstructions | Clean the path and prism surface |

Every Month | The presence of moisture and water (Visual inspection of prism inner surface) | 1. Turn on the lamp body 2. Clean, dry and check 3. Replace O-rings and other damaged parts |

Every Two Month | Tighten the screw | Check the lamp body tightness bolts are locked |

After 1200 hours 6.6A operation | Change Lamp Bulbs | Recommended When the service life is reached, replace the lamp systematically. At rated power (6.6A), up to 1200 hours. But in actual operation, the lamp life may reach 2000 to 4000 hours |

Notes:

① It is recommended to increase the number of maintenance during the rainy season to ensure the normal operation of the lamp.

② It is suggested that the system replace the lamp when the lamp reaches the service life (80% light intensity)

Change bulbs:

Turn off the power, open the lamp cover, unplug the lamp pin. Holding the thumb and forefinger on the tail of the bulb, rotate the bulb to align the circular notch in the lower part of the lamp tray with the clip of the lamp holder and remove the bulb backward. Thumb and forefinger holding the tail of the bulb, the lower circular notch of the lamp tray alignment snap bracket bracket, rotate the bulb 90 degrees, so that the lamp bracket buckle stuck lamp panel, the lamp pin into the holder can be.

Notes:

① Never replace the lamp from the front of the lamp; remove the lamp prism will destroy the lamp beam.

② The working position of the bulb is the direction of the notch of the circular card slot and the direction of the bulb holder bayonet.